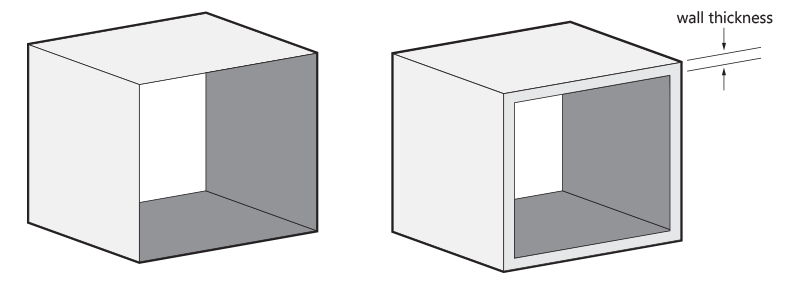

Here, partial production steps executed by an industrial robot arm, such as large-format additive manufacturing, mechanical surface preparation, bonding and assembly process are explained. The research shows a parametric design process to enable the seamless integration of digital analytic tools.įurthermore, this process shows the potentials and challenges of the digital manufacturing of a thin glass composite panel. It explains the idea of a digital “fle-to-factory”-workfow which includes Computer-Aided Design (CAD), Engineering (CAE) and Manufacturing (CAM). This paper presents an exploratory attempt on the digital manufacturing of thin glass composite façade panels with an industrial robot. Based on the sandwich theory, the fexible thin glass can be combined with a 3D-printed open-cell polymer core to form a very rigid yet lightweight composite element. In addition to the ecological benefts of more efcient use of resources, architects can anticipate new design freedoms with thin glass. The use of thin glass promises to enable a variety of construction industry pursuits. I would suggest to simply the inner geometry, and you can thicken the walls of an object using the 'Solidify' modifiers in Blender.Īlthough, I think it would be best to just rebuild it from scratch in Blender and make the walls thicker from the start.Source: Architecture, Structures and Construction, Springer That would also explain why your print fails: the printhead has to do too many retractions. That being said, my main concern, if I interpret your gif right, is the insane movements of the printer head! If I'm not mistaken, the thin red lines on the gif must represent the movements of the printhead, and they're all over the place! With such a geometric pattern inside, I would expect the printhead to follow the lines, but yours seems to jump all around. The gif, while fast, seems to show some problem arising when the model is sliced and it seems that there are missing layers and holes when I compare the end of the gif to the picture of the 3D model you provided. I believe that the inner geometry of the piece is unnecessarily complex, thus why it generates so much problem.

It works most of the time, though you often have to check the model and redo some stuff. That's the quick, though often dirty, solution. The quick solution to make a Blender model of this is to export it as an stl then import it in Blender.

0 kommentar(er)

0 kommentar(er)